+86-139 6175 2624

Evaporative condenser and closed cooling tower

Release date: 2017-10-24 14:36:05 Visits: 1109

Evaporative condenser

Small closed cooling tower

Equipment factory

Workshop corner

Customer case

Customer case

First, the equipment advantages

Large internal space, maintenance is very convenient.

Closed loop, to eliminate debris caused by debris.

Heat exchanger with modular stacking, can be installed and disassembled layer by layer.

Using soft water cycle, no scale generation.

No pool, small footprint, easy to address.

Automatic digital temperature control, energy saving and environmental protection.

Simple operation, low maintenance costs.

Second, the main components of the technical performance specifications

Host → cooling tower host mainly by the shell, copper cooler, exhaust system, spray system, dehydrator, sink and other components

Shell → cooling tower shell made of high quality hot-dip galvanized sheet thickness of 2mm, the appearance of beautiful appearance (color can be specified by the user); CNC machine tool scissors, folding, red after welding without welding assembled, accurate size smooth.

Cooler → Cooler is a key part of the cooling tower, the internal cooling medium, the external air-cooled and water spray to meet the cooling requirements; cooler international standard T2 deacidified copper production, all for the naked copper round Tube, without fin, in order to ensure its cooling effect; the connection between the copper pipe and the elbow using silver electrode welding, welding less and good quality.

Copper cooler

Exhaust System → The main function of the exhaust system is to exhaust the saturated hot and humid air inside the cooling tower, which is composed of the air inlet grilles, blowers and protective covers. The fan adopts an aluminum shell and three blowers to increase the service life.

Fan

Sprinkler system → Sprinkler system is mainly composed of sprinkler pump, connecting pipes, sprinklers and other components. When the temperature exceeds the set temperature, the system control automatically open the sprinkler system to ensure that the cooling temperature to meet the requirements.

Dehydrator → Dehydrator main role is the exhaust system will spray water and hot steam to the water out; the use of PVC efficient dehydrator (professional manufacturer custom), so that the water flow rate of less than 0.01%, making the device placed in water Foggy areas are possible.

Dehydrator

The main function of the sump → sump is to store the spraying water, which is composed of a water tank, a float valve, a water inlet and a sewage outfall.

→ The standard configuration circulating pump is 1, consider the reliable factor of the equipment, the user can then choose a spare pump, when the main pump fails, you can directly switch the use of spare pumps to ensure that the equipment is constantly water.

→ The cooling tower is equipped with pressure display at the water inlet. Pressure is also displayed at the water inlet of the equipment to be cooled. The pressure drop can be read through the pressure difference so as to achieve effective cooling to ensure that the equipment is in safe water flow range.

→ Cooling tower at the outlet with a temperature display, and through the digital temperature controller control sprinkler system to adjust the inlet and outlet water temperature, the closed cooling tower within the specified water temperature range of equipment for continuous and efficient cool down.

Stainless steel water tank and circulating pump

→ Equipment Environment Requirements:

1. Altitude not exceeding 3000m;

2. Ambient temperature in the range of 0-40 ℃; (0 ℃ below the area need to take antifreeze measures)

3. Use the region''s wettest month daily maximum relative humidity of not more than 90% of the average monthly average

4. There is no conductive dust around, explosive gases and can seriously damage the metal and the insulation of corrosive gases.

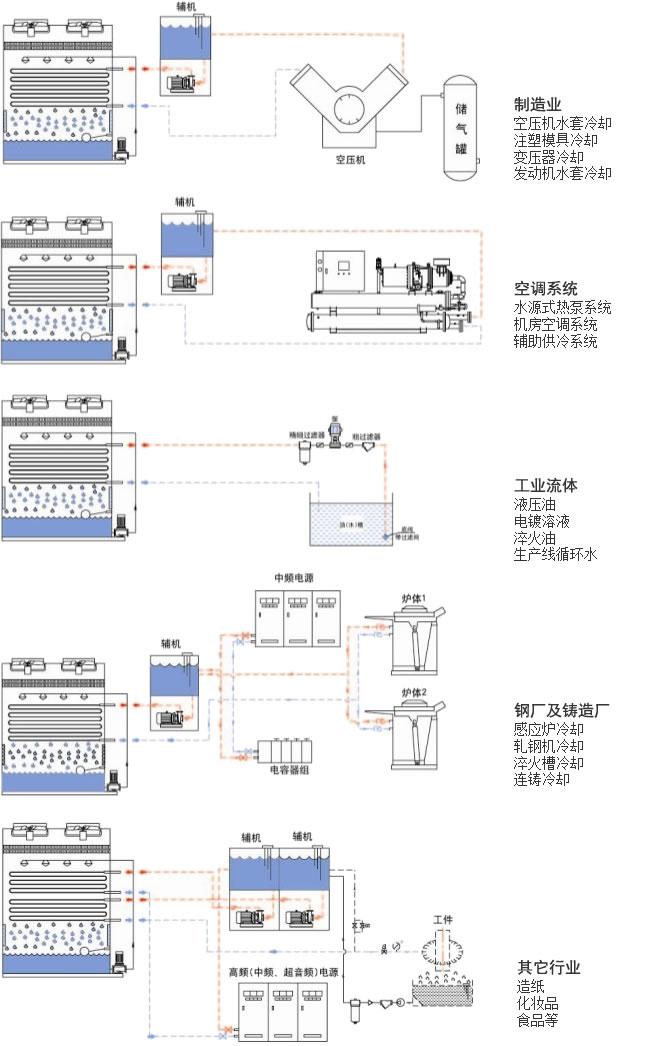

Third, the scope of application

Previous: Coarse particle separator